FROM THE PERFECT LAST TO THE RIGHT SHOES

The last is the core for the concept, the design and the production of each shoe.

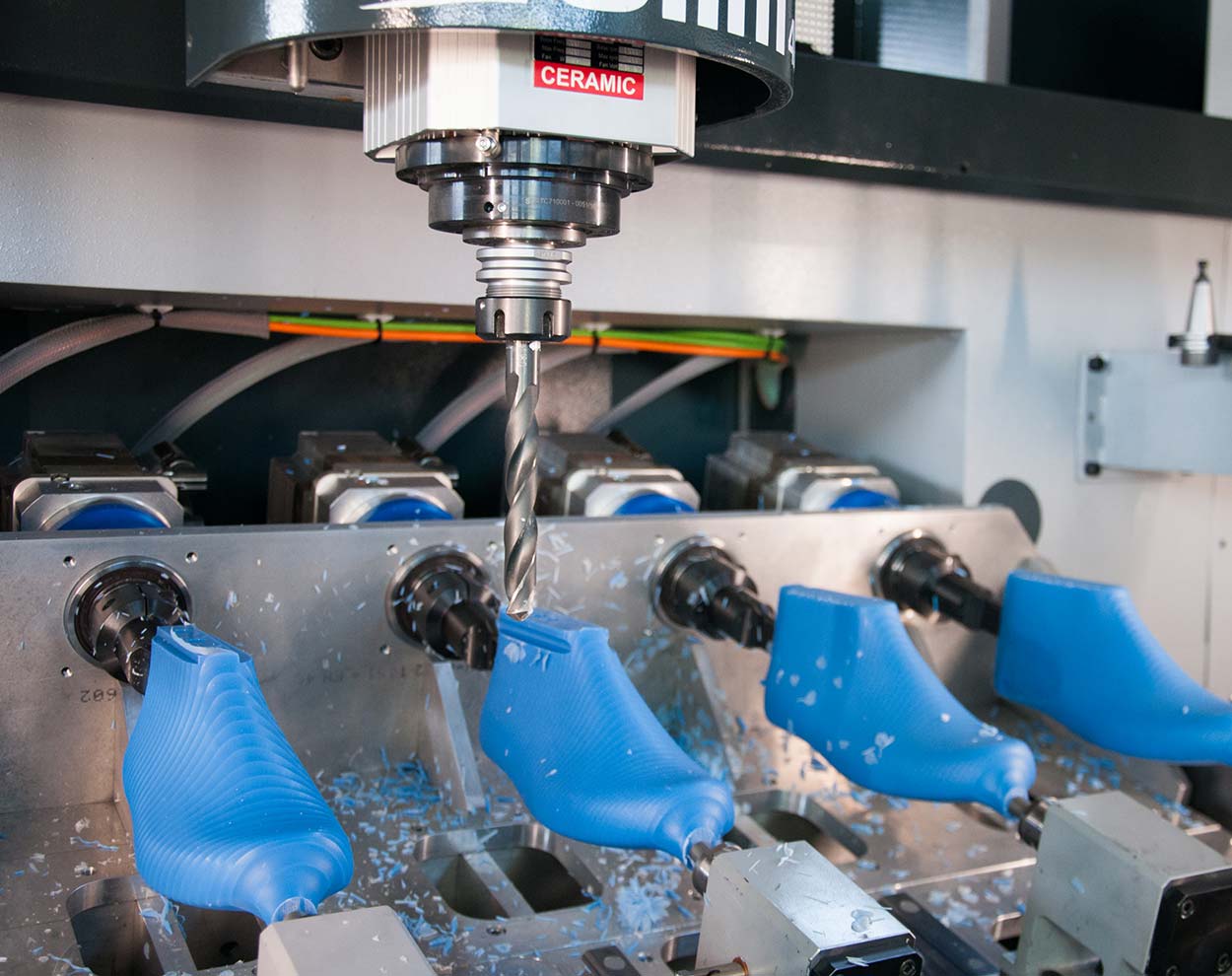

S.L.I.M 4.0 - A NEW PRODUCTION METHOD

Learn moreShoe Last Integrated Manufacturing – una piattaforma software integrata con macchinari all’avanguardia che semplifica le procedure e riduce drasticamente le tempistiche per la prototipazione e produzione di forme di alta qualità, con risultati in termine di precisione fino ad oggi inarrivabili.

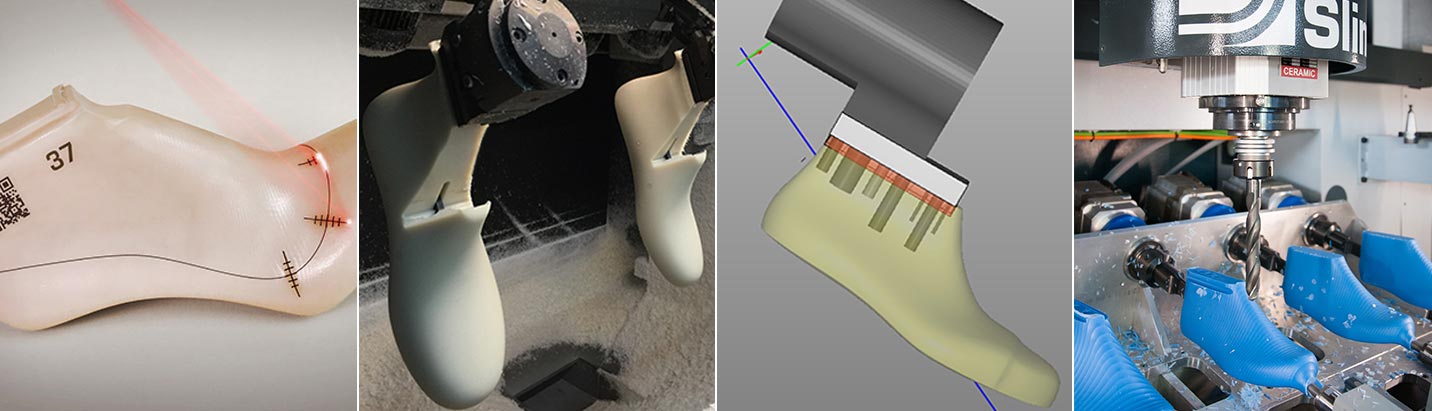

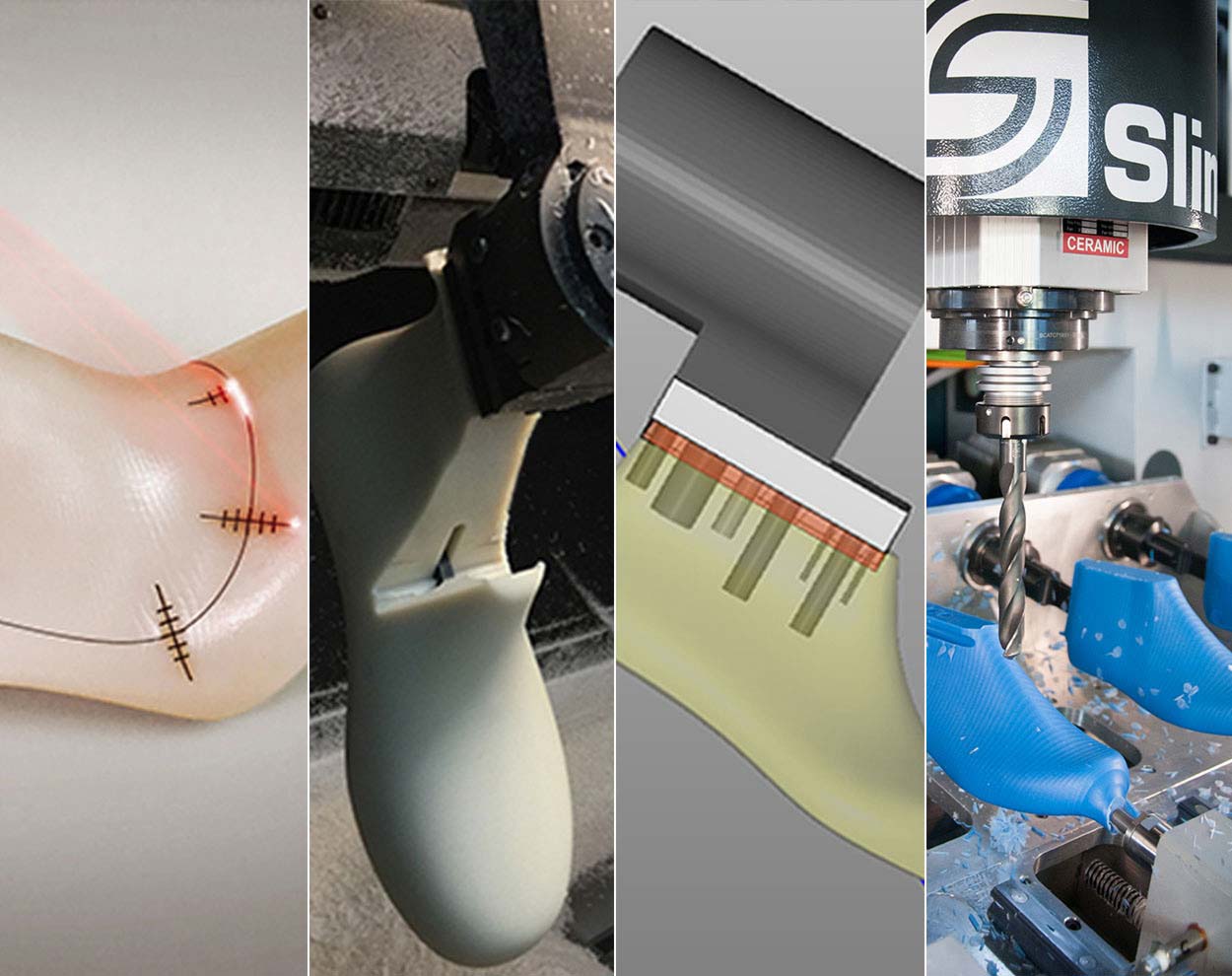

SDMARK - SHOE LAST LASER MARKING

Learn moreThe brand new Newlast patented system enables to automate the shoe last marking process, thanks to the interaction between a specific S.L.I.M. 4.0 software module and the innovative SDMARK machine.

SDMC - PRODUCTION OF TECHNICAL SHOE LASTS

Learn moreBy setting different production cycles together with Software Module S.L.I.M. 4.0, shoe lasts can be prepared to be used on automated production cycles or for automatic sole injection systems.

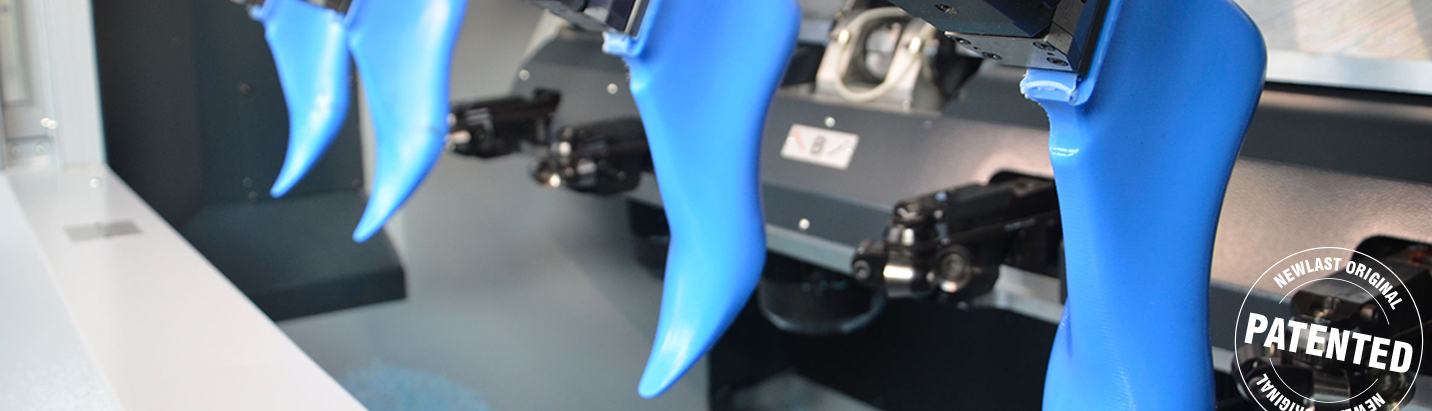

NEWLAST SDF - THE COMPLETE PRODUCTION OF THE SHOE LAST

Learn moreThanks to the dovetail clamp, the SDF systems, Newlast patented, finish the shoe lasts, in a single work cycle, even on the toe and on the heel, deleting any manual intervention.

S.L.I.M 4.0 - A NEW PRODUCTION METHOD

Learn moreShoe Last Integrated Manufacturing – a software operating system integrated with modern machines that eases procedures and drastically reduces production time for high quality shoe lasts prototyping and manufacturing with unrivaled precision.

SDMARK - SHOE LAST LASER MARKING

Learn moreThe brand new Newlast patented system enables to automate the shoe last marking process, thanks to the interaction between a specific S.L.I.M. 4.0 software module and the innovative SDMARK machine.

SDMC - PRODUCTION OF TECHNICAL SHOE LASTS

Learn moreBy setting different production cycles together with Software Module S.L.I.M. 4.0, shoe lasts can be prepared to be used on automated production cycles or for automatic sole injection systems.

NEWLAST SDF - THE COMPLETE PRODUCTION OF THE SHOE LAST

Learn moreThanks to the dovetail clamp, the SDF systems, Newlast patented, finish the shoe lasts, in a single work cycle, even on the toe and on the heel, deleting any manual intervention.

S.L.I.M 4.0 - A NEW PRODUCTION METHOD

Learn moreShoe Last Integrated Manufacturing – a software operating system integrated with modern machines that eases procedures and drastically reduces production time for high quality shoe lasts prototyping and manufacturing with unrivaled precision.

SDMARK - SHOE LAST LASER MARKING

Learn moreThe brand new Newlast patented system enables to automate the shoe last marking process, thanks to the interaction between a specific S.L.I.M. 4.0 software module and the innovative SDMARK machine.

SDMC - PRODUCTION OF TECHNICAL SHOE LASTS

Learn moreBy setting different production cycles together with Software Module S.L.I.M. 4.0, shoe lasts can be prepared to be used on automated production cycles or for automatic sole injection systems.

NEWLAST SDF - THE COMPLETE PRODUCTION OF THE SHOE LAST

Learn moreThanks to the dovetail clamp, the SDF systems, Newlast patented, finish the shoe lasts, in a single work cycle, even on the toe and on the heel, deleting any manual intervention.

THE FUTURE OF FOOTWEAR: 3D FOOT ACQUISITION

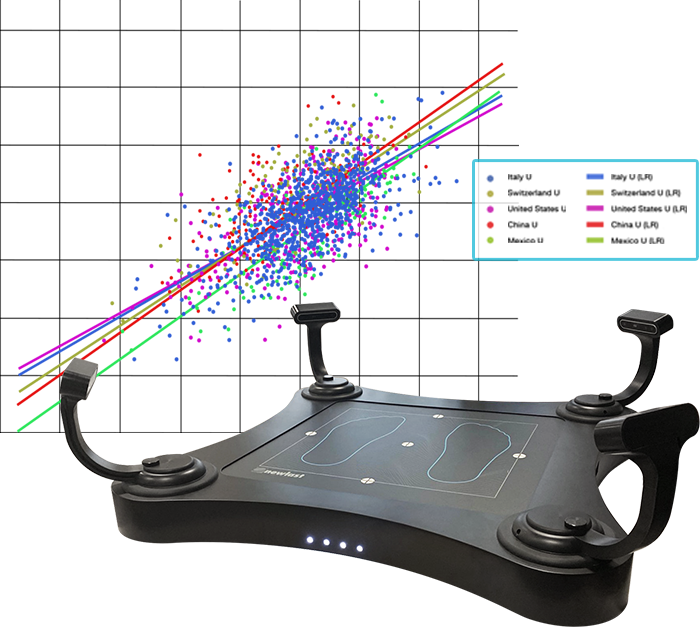

Having reliable data on the morphology of the feet of consumers is what nowadays can make the difference for both, industrial production as well as smaller factories.

The obsolete methodologies currently used for size development don’t take in account the morphological differences due to important parameters like geographical and demographic ones. Furthermore, there is no standard development system: this causes confusion in the consumer who doesn’t find a continuity of correspondence in sizes and other characteristics, even in models that he/she identifies as similar.

Overcoming this limit is the decisive step for any Brand that wishes to offer its consumers a truly innovative and satisfying omni-channel shopping experience.

By using the Right Shoes feet detection and data analysis services and choosing the highest standards of quality, repeatability and precision that Newlast technology guarantees, the Brand is now able to offer footwear, produced on an industrial scale, that is truly optimized for the needs of each customer.

Right Shoes functionality

FEET COLLECTION

The innovative Right Shoes scanning technology allows the collection of feet 3D information in a dedicated database.

ANALYSIS AND STATISTICS

By downloading the collected data, the RS-FeetMeasures software allows the creation of graphs and statistics on foot morphology.