NEW DIGISCAN.SL/evo!

Research is the focus of our company philosophy; we will never stop to underline it.

For this reason, we aim to constantly develop all our products with the implementation of all the best technological solutions available.

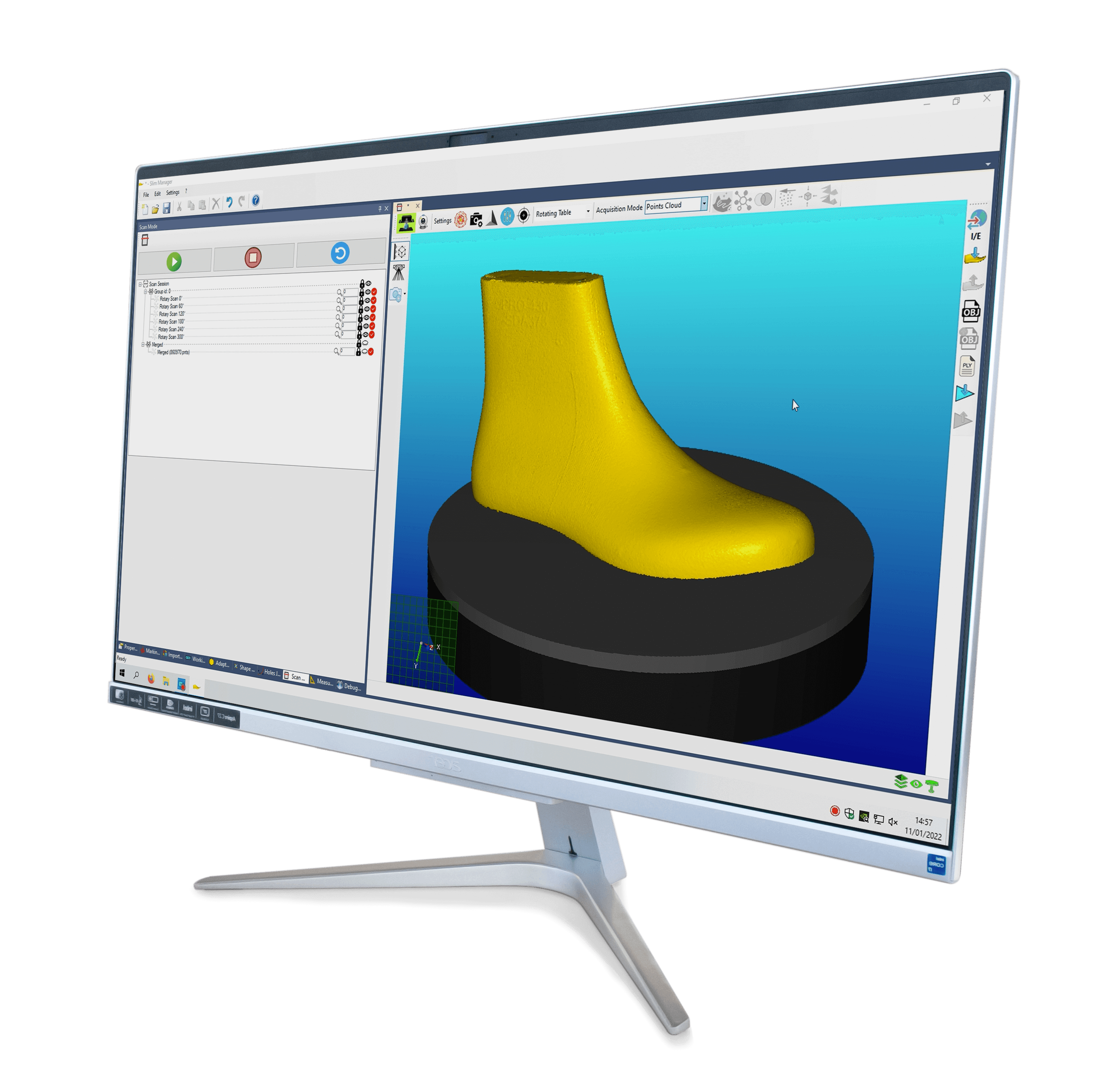

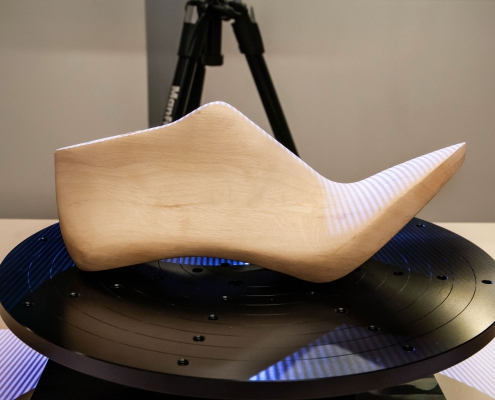

In this context, we would like to introduce you our NL.DIGISCAN.SL/evo, the new advanced version of our structured light digitizer. The new faster and more efficient scanner is a deeply improved product, both for optical component and especially for software, with a very interesting price.

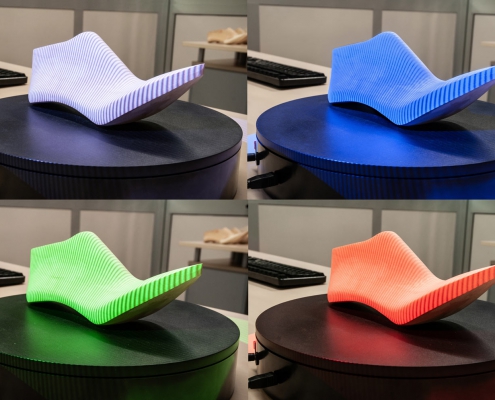

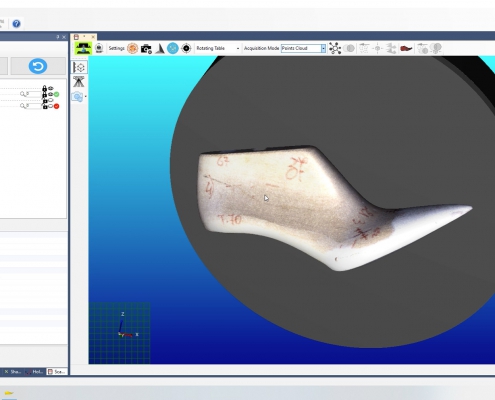

DIGISCAN.SL/evo can be set to project white, green, blue or red light, in order to reduce reflections and optimize the result on different types of plastics or other materials. It can also be possible to automatically acquire information about colour and texture of the scanned object.

As usual, each scan can be saved in a standard format (.FRV, .STL, .OBJ or .PLY) ready to be used in the Newlast production cycle.

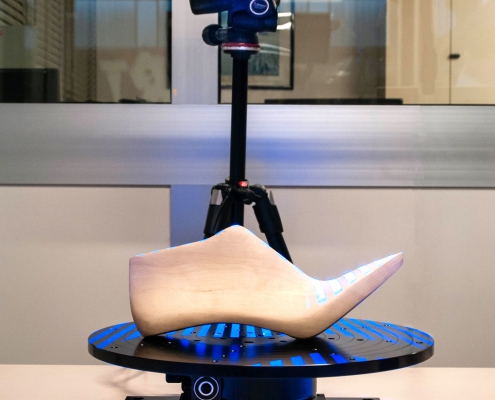

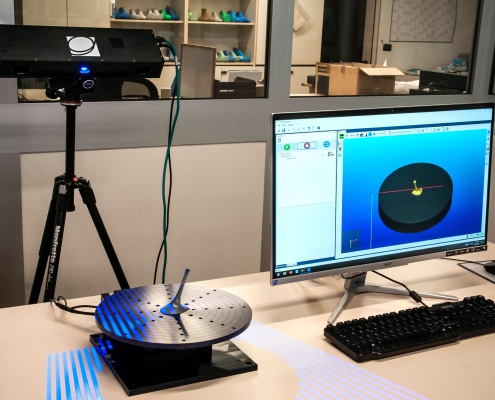

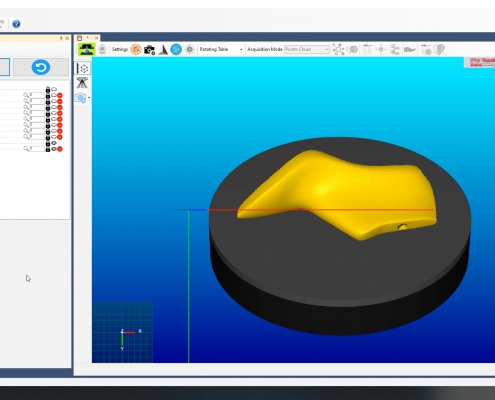

You can find the same features such as compactness, lightness and portability that have determined the success of the previous LIGHT version (.SL/L). The optical head, supported by a tripod, is supplied together with the new All In One PC and a motorized rotary table, to allow rapid object scanning.

Thanks to the new “evo” version, time savings is guaranteed!

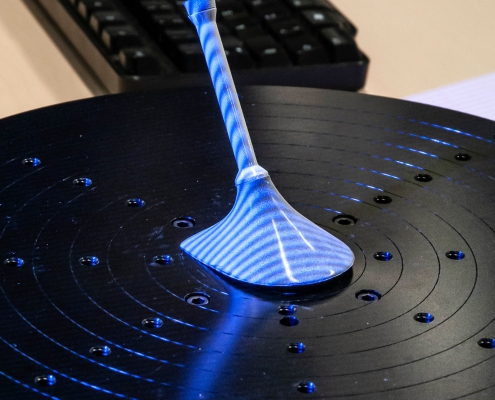

Until today, you needed several scans from different points of view on the object to have a complete 3D, but now only two positions are enough. It is also possible to add a “FreeScan” according to the operator’s needs. The projection of the light bands can also be considerably speeded up. Moreover, an energy-saving mode has been included, to preserve the LED projector life.

BETTER DETAILS DETECTION

FAST ACQUISITION

OPTIMIZATION ON DIFFERENT MATERIALS

LONG LIFE AND ENERGY SAVING

DIGITIZING MODULE – S.L.I.M. 4.0 :

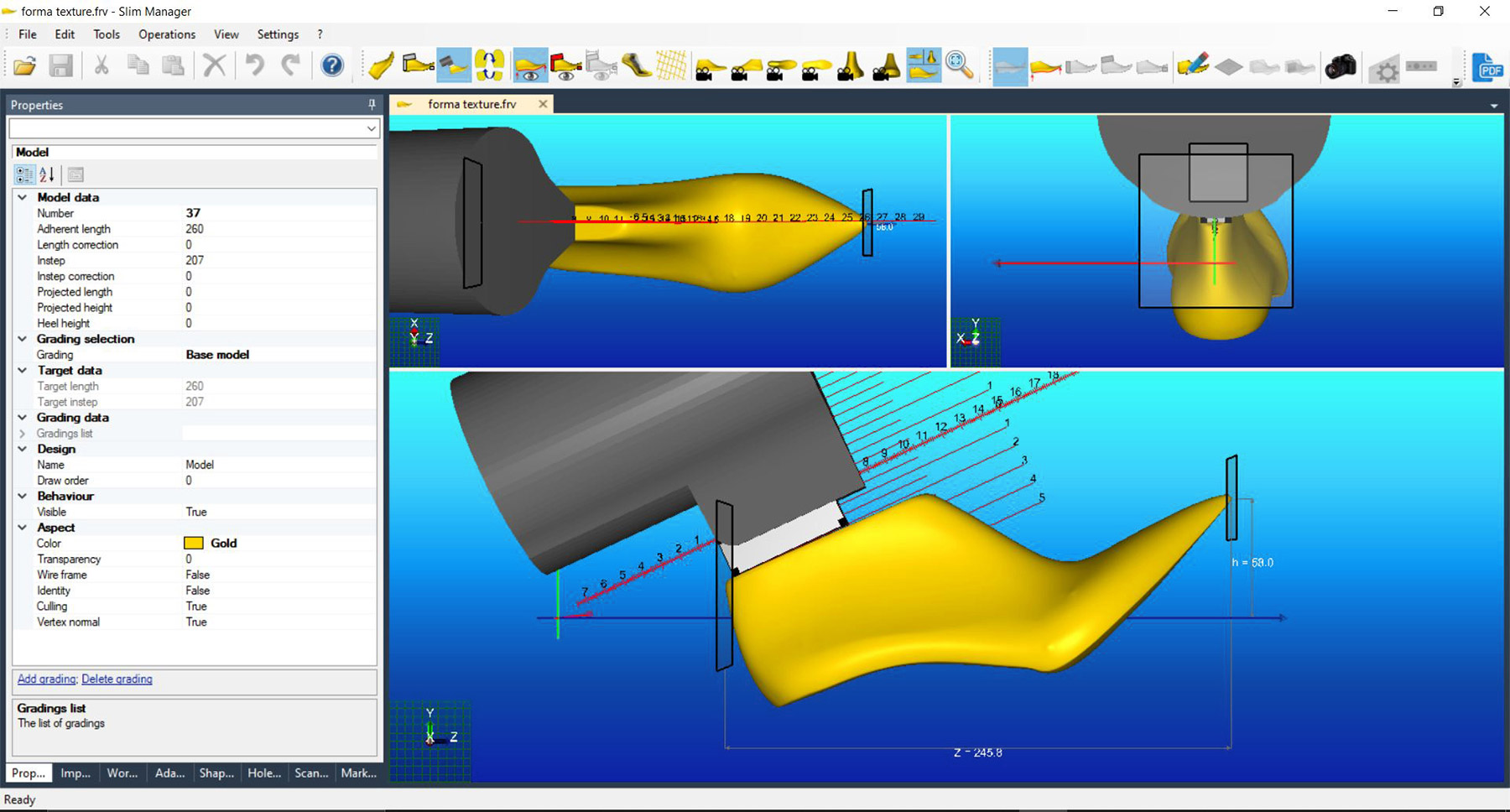

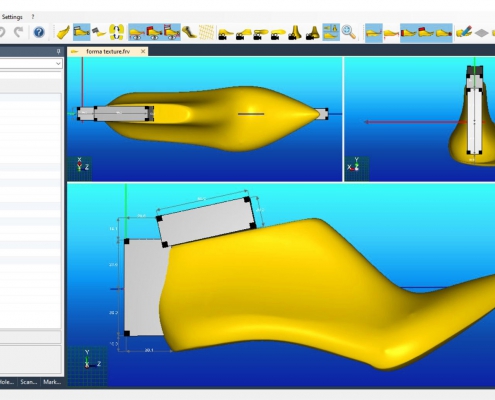

The scans management with the new software SLIM 4.0 – DIGITIZING MODULE brings NL.DIGISCAN.SL/evo in the integrated and automated system S.L.I.M. 4.0.

The new software allows the object interaction even during the scanning phase and enables the automatic alignment of the obtained acquisitions. Scans can be deleted without losing the project, and single points can be selected and removed.

The scanning management with a platform developed for the 360 ° shoe last management, such as S.L.I.M. 4.0, lets the operator carry out any type of operation, directly connecting all other platform modules.

For example, it is possible to directly access the NEW SETUPMODEL MODULE, to include the supports for shoe lasts clamping on SDF machines.

Thanks to the potentiality of this module, it is possible to obtain the complete shoe last .FRV ™ file, to send it directly to the machines.

COMPARISON MODULE – S.L.I.M. 4.0 :

A further innovation of this software module is its inclusion in the DIGISCAN.SL/evo kit: it allows the operator to make an accurate comparison with both the 3D file and on two shoe lasts, obtaining all the necessary reports.