SHOE LAST MARKING

In Newlast, we always supply cutting-edge solutions focusing on our customer’s problems and we are used to introduce innovative tools to open new ways of producing.

Our Company has overcome a new technological barrier in the world of Shoe Lasts making. After years of studying and hardware and software development, today we can ensure total freedom to shoemakers, they will no longer face limits in the lasts marking procedure, as a results, they will considerably improve shoe production method, assembly process, speeding up the entire process.

Obsolete systems, still used today, limit the possibilities of marking shoe last with accurate, clear, and repeatable references.

Due to lack of adequate technological solutions, Last-Makers have been facing many problems to satisfy the increasing requests and demands of their customers.

LIMITS OF actual “TRADITIONAL” MARKING SYSTEMS:

- Constrains in markable geometries

- Inability to define and determinate precisely where the shape should be marked

- Copying marks from sample to basic model

- Problems related to precisely set and measure the height of the heel shoe line

- Difficult in applying additional information and useful data on the last surface (shoe construction data, 3D link to the last, customer data, etc …)

- handmade Guidelines during the pre-assembly phase in the shoe factory

- operations managed by manual positioning with obvious precision and repeatability limitations

- Complexity in providing adequate support to brands in their need for increased precision

- Impossibility in providing new marking solutions

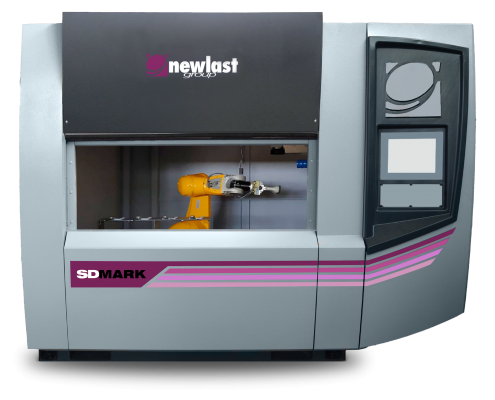

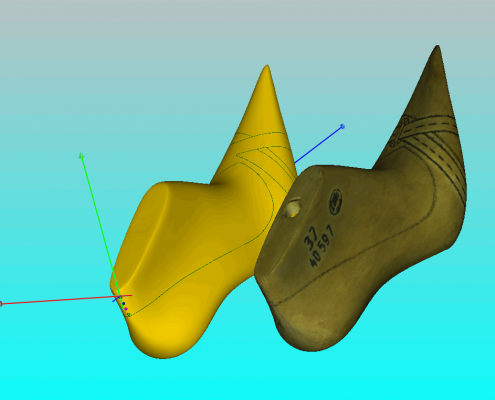

SDMARK is not only a Machine but It’s a complete System where the most advanced laser marking technology meets the new specific S.L.I.M. software module for defining signs, lines, bar codes, QR codes.

A real help also in the supply chains where expert hands are more and more difficult to find.

ADVANTAGES OF THE NEWLAST MARKING SYSTEM:

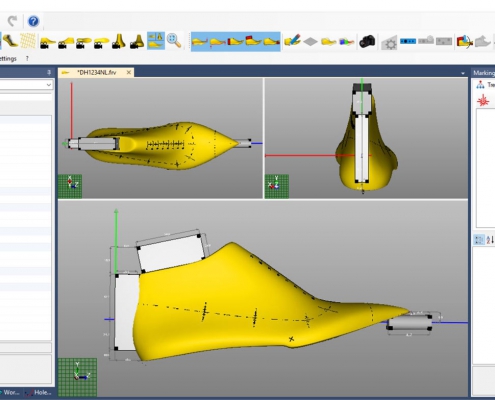

- Computerization process, everything is defined on the 3D of the Shoe-last.

- Precise definition through parameters and or copy of 3D files

- For hand-marked lasts you can use Digiscan 3D texture scans to copy signs/lines

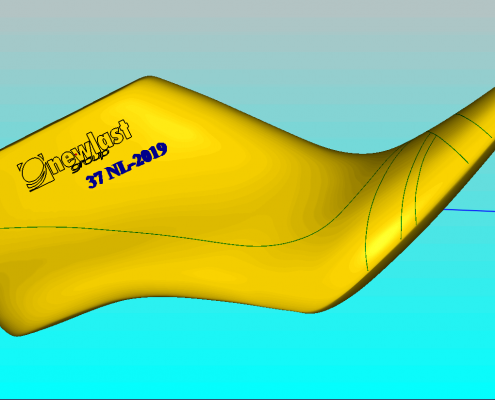

- Possibility to add additional data by generating a bar and QR code image (shoe construction data, 3D link to the shape, customer data, etc …)

- Accuracy, repeatability, 3D control of all marked sign

- Ability to satisfy new brand requests by solving all current problems

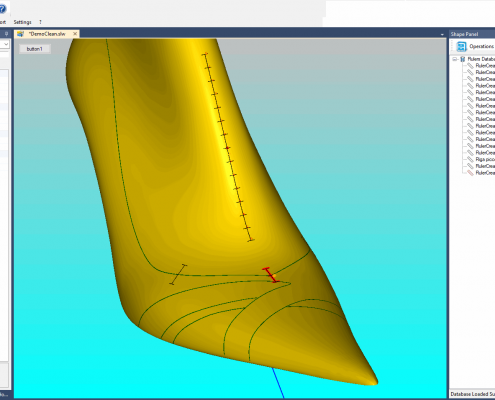

- Possibility to have reference style lines for décolleté assembly, sandal laces, open toe, cut sandal flip flops, and much more.

- 3D projects saved and archived for later reproduction

- Size grading management, geometry preservation in real-time over the 3D last surface

- Heel height construction shoe line management and grading control

Brands and all those who physically “create” the footwear can have the greatest advantages from this new system. SD-MARK allows the production of “smart” shoe-lasts and opens up to a new world of geometric references that provide decisive support to the lasts production and shoe assembly phases.