DAEHAN: SDF TURNS INTO REALITY

From the beginning of 2019, the new production line at DaeHan Group has been started up.

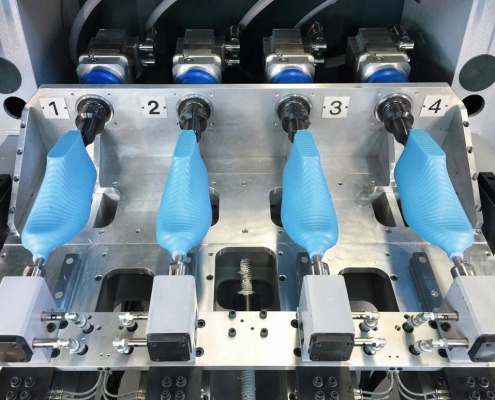

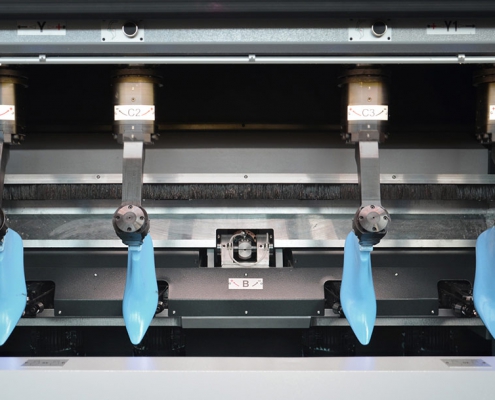

The SDFHS finishing machines, together with the multifunctional milling centre SDMC4 – for special drilling and milling cycles – and the newest structured light technology digitizer DIGISCAN.SL, are already working at full capacity to produce high quality technical shoe lasts.

Thanks to Newlast Slim Manager 4.0 software, during the design phase, it is possible for the model makers to integrate to the .FRV file: the standard turning cycle information as well as the data of the main operations for the placement of metal plates that will be used for the clamping and the movement of the shoe last during automatic and injection production cycles.

Productivity improvement, advanced manufacturing of shoe lasts and highest precision and repeatability levels: these are the core elements that make DaeHan the first Korean Group at the top of the worldwide shoe last industry.