FMT INVESTS IN S.L.I.M. 4.0 SYSTEM

“I do not see a tomorrow without automation”, with these words Mr. Gianmarco Gemme, owner of Formificio Milanese Team, makes immediately clear the reasons for the important decision to invest in the Newlast S.L.I.M. 4.0 system.

“Automation will be the future key word for footwear. This is demonstrated, among other things, by all the productions that are returning to their countries of origin or in the immediate vicinity. We must be ready. ” states Mr. Gianmarco. FMT is one of the world leaders in terms of technical lasts for direct injection and automation and once again it proves to be a pioneer in the search for innovative solutions for its production system that also includes the SDF HS, the cornerstone of the entire process.

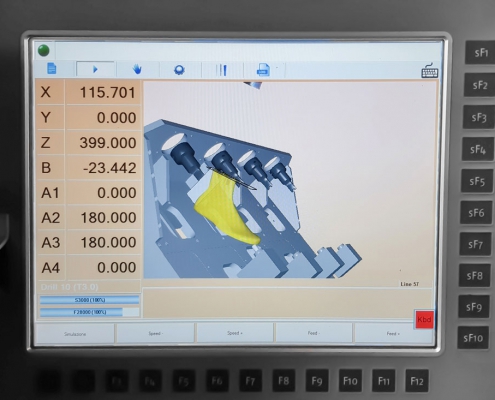

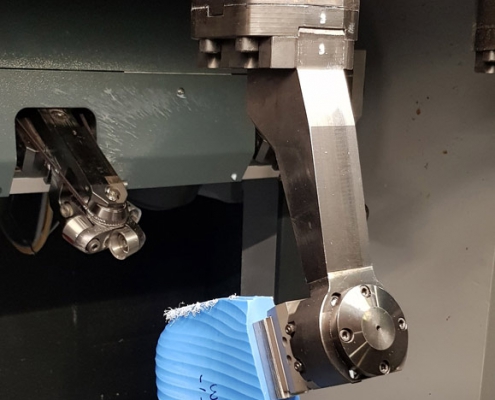

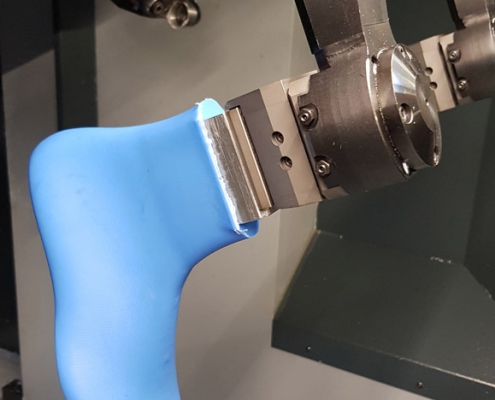

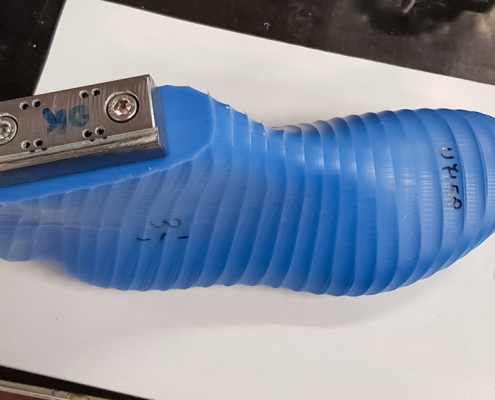

The S.L.I.M 4.0 system is now operating at full capacity at Formificio Milanese, this will allow them to take a further step forward and to be ready for that process of modernization that will soon change not only the injected product, but also the traditional one. Being able to guarantee not only precision, but also productivity and punctual deliveries will be a crucial aspect. Furthermore, the new system allows to completely manage the last during the prototyping of the model and to improve the production, by guaranteeing to the customer the highest accuracy.Newlast and FMT: a cooperation that began during the first numerical control revolution in the production of shoe lasts, which continues in the name of innovation and advanced technology for the future.View Arsutoria article

“Automation will be the future key word for footwear. This is demonstrated, among other things, by all the productions that are returning to their countries of origin or in the immediate vicinity. We must be ready. ” states Mr. Gianmarco. FMT is one of the world leaders in terms of technical lasts for direct injection and automation and once again it proves to be a pioneer in the search for innovative solutions for its production system that also includes the SDF HS, the cornerstone of the entire process.

The S.L.I.M 4.0 system is now operating at full capacity at Formificio Milanese, this will allow them to take a further step forward and to be ready for that process of modernization that will soon change not only the injected product, but also the traditional one. Being able to guarantee not only precision, but also productivity and punctual deliveries will be a crucial aspect. Furthermore, the new system allows to completely manage the last during the prototyping of the model and to improve the production, by guaranteeing to the customer the highest accuracy.Newlast and FMT: a cooperation that began during the first numerical control revolution in the production of shoe lasts, which continues in the name of innovation and advanced technology for the future.View Arsutoria article